As an Amazon Services LLC Associates Program participant, we earn advertising fees by linking to Amazon, at no extra cost to you.

Safety Tips for Operating a Wood Cutting Machine

Safety should always be the number one priority when operating a wood cutting machine. As someone who is passionate about arts and crafts, I understand the excitement of diving into a new project. However, it is crucial to remember the potential dangers that come with using power tools. Always wear appropriate safety gear such as goggles, gloves, and ear protection when operating a wood cutting machine. Additionally, make sure to read the manufacturer’s instructions carefully and familiarize yourself with the machine before using it. Lastly, never operate the machine if you are feeling fatigued or distracted. Safety first, creativity second!

Importance of Choosing the Right Wood Cutting Machine

When it comes to woodworking projects, having the right wood cutting machine can make all the difference in the quality and efficiency of your work. Let me share with you some key reasons why selecting the correct tool is crucial:

- Accuracy: A reliable wood cutting machine ensures precise cuts, leading to professional-looking results.

- Safety: Investing in a machine with built-in safety features can protect you from potential accidents and injuries.

- Efficiency: The right machine can help you complete projects faster, saving you time and effort in the long run.

- Versatility: Choosing a machine that offers various cutting options allows you to tackle a wide range of projects with ease.

- Durability: Opting for a high-quality wood cutting machine ensures longevity and reliable performance for years to come.

Benefits of Using a Wood Cutting Machine

Why limit your creativity with manual tools when you can revolutionize your woodworking projects with a wood cutting machine? From precise cuts to increased efficiency, the benefits are endless. Save time and effort as you effortlessly slice through wood like a pro, enhancing your craft and bringing your artistic visions to life. Say goodbye to uneven edges and hello to professional-looking results. Experience the satisfaction of achieving intricate designs with ease, boosting your confidence and pushing your skills to new heights. Trust me, once you go wood cutting machine, you’ll never look back!

Types of Wood Cutting Machines

Welcome to our arts and crafts blog! Today, I want to talk about wood cutting machines. As a crafting enthusiast, I know how important it is to have the right tools for the job. Wood cutting machines come in various types, each serving a different purpose in your woodworking projects. From band saws and table saws to scroll saws and miter saws, the options can be overwhelming. Do you need precise cuts or curved designs? Are you working with soft or hardwood? Understanding the types of wood cutting machines available will help you choose the best one for your creative endeavors. Stay tuned for more tips and recommendations!

Maintenance Tips for Wood Cutting Machines

As a seasoned crafter, I’ve had my fair share of experiences with wood cutting machines. These are the maintenance tips that have kept my machines running smoothly and efficiently.

- Always clean the machine after each use to prevent sawdust buildup and ensure optimal performance. A clean machine is a happy machine!

- Regularly inspect the blade for any dullness or damage, and replace it as needed to avoid accidents and poor cutting results. Sharp blades are essential for clean cuts!

- Check and tighten all bolts and screws to prevent vibrations and ensure the safety of the machine while in operation. A sturdy machine is a safe machine!

- Apply a lubricant to the moving parts of the machine, such as the blade and bearings, to reduce friction and extend the lifespan of the components. A well-oiled machine runs smoothly!

- Store the wood cutting machine in a dry and well-ventilated area to prevent rust and corrosion, and cover it when not in use to protect it from dust and debris. Proper storage is key to prolonging the life of your machine!

Carbide 3D Community Site · CNC not cutting completely through wood · CNC Machines Shapeoko · Guy77 (Gaetano isidori) April 7, 2022, 10:28pm 1.

CNC not cutting completely through wood – Shapeoko – Carbide 3D …

Dec 15, 2021 … I am using Smart Cut app on my iPhone. You enter the stock size, kerf size and the pieces you want to be cut. It will show you how to fit you …

Is there an easy online tool to visualize cutting wood into pieces? : r …

Mar 11, 2024 … This is my site, so I can give my total honest thoughts and feelings on the topic of cutting wood with Cricut Maker, or any Cricut machine. If …

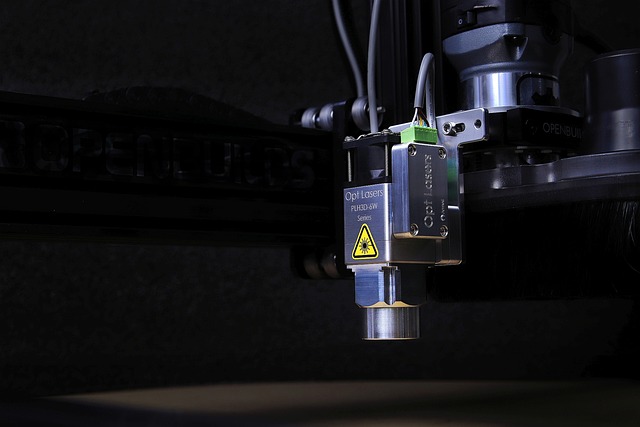

… machine. Laser Cutter. full spectrum laser cutter. Full Spectrum. The Full Spectrum Laser Cutter has a cutting area of 20" x 12". It can cut wood, acrylic …

Jan 7, 2017 …Wood Carving Tool Storage · Table With Cooler. BUILD LOG: jon's … a machine that is cutting plywood into pieces · BASIL …

As an Amazon Services LLC Associates Program participant, we earn advertising fees by linking to Amazon, at no extra cost to you.

What safety equipment should I wear when using a wood cutting machine?

When using a wood cutting machine, safety should always be a top priority. It is crucial to wear the proper safety equipment to prevent accidents and injuries. I highly recommend wearing safety goggles to protect your eyes from flying wood chips, ear protection to prevent hearing damage from the machine’s noise, and sturdy gloves to protect your hands from cuts and splinters. Additionally, wearing close-toed shoes with good traction can help prevent slips and falls. Remember, safety first!

How often should I sharpen the blade of a wood cutting machine?

I sharpen the blade of my wood cutting machine every month. Keeping the blade sharp ensures clean cuts and prevents accidents. Regular maintenance is key to a smooth crafting experience. Don’t wait for the blade to dull before sharpening it, as this can damage the machine and compromise safety. Stay proactive and sharpen the blade frequently. Trust me, it’s worth the time and effort.

Can a wood cutting machine be used for different types of wood?

Yes, absolutely! A wood cutting machine is incredibly versatile and can handle a variety of wood types. Whether you’re working with softwood like pine or hardwood like oak, a quality wood cutting machine can easily adapt to different materials. Just ensure you adjust the settings properly and use the right blade for the specific wood you’re cutting. With the right machine and know-how, you can efficiently cut through any type of wood for your arts and crafts projects.

Wood cutting machines vary from table saws, bandsaws, to CNC routers, offering diverse options for creative projects in arts and crafts.

For woodworking projects, using a wood cutting machine is essential for enhancing efficiency and precision. This tool streamlines the cutting process and ensures accurate results, making it a valuable asset in any workshop.

Regular maintenance and proper safety precautions are essential when operating a wood cutting machine. Neglecting maintenance can lead to accidents and equipment malfunction, jeopardizing your safety and the quality of your projects.

Choosing the right blade and adjusting settings correctly can significantly impact the quality of wood cuts. It’s crucial for precise and clean results in your arts and crafts projects.