As an Amazon Services LLC Associates Program participant, we earn advertising fees by linking to Amazon, at no extra cost to you.

Choosing Quality Materials

Selecting the right materials is essential for creating successful arts and crafts projects.

- Prioritize durability. Cheap materials may save money now, but they often compromise the longevity of your project.

- Consider the texture. The feel of materials affects the overall experience and finish of your art piece.

- Research brands. Some brands provide consistent quality, making them trustworthy choices.

- Test materials before committing. Small samples can help you gauge suitability for your project without a large upfront investment.

- Be mindful of the environment. Choosing eco-friendly options not only supports sustainability but can elevate your work’s intention.

Popular Projects Using PVC Laser Cutting

Exploring the creativity that can be unleashed through PVC laser cutting, I’ve compiled some standout projects that inspire and excite.

- Custom Signage: I love creating personalized signs for home and business. Laser cutting allows for intricate designs that really stand out.

- 3D Models: There’s nothing quite like designing and cutting 3D models from PVC. The precision is phenomenal, and the results are always impressive.

- Jewelry Making: I’ve experimented with using laser-cut PVC pieces to craft unique jewelry. The possibilities—from earrings to pendants—are endless!

- Home Decor Items: Creating wall art or decorative items is one of my favorite uses for PVC. The crisp edges and customizable shapes can completely transform a space.

- Educational Tools: As a hands-on crafter, I’ve created educational resources like puzzles and charts. Laser-cutting makes these projects precise and engaging.

- Cosplay Accessories: For fellow cosplayers, PVC offers a lightweight and durable option for crafting helmets, props, and armor pieces. It’s become a staple in my toolkit.

- Business Cards: Why settle for basic? Laser-cut business cards made from PVC make an unforgettable first impression with sleek edges and custom shapes.

Maintaining Your PVC Laser Cutting Machine

Regular maintenance of your PVC laser cutting machine is crucial for optimal performance. I make it a habit to clean the lens and mirrors after every use to prevent residue buildup. Checking and tightening all screws and bolts keeps everything secure and functioning correctly. I also regularly inspect the belts and pulleys for wear and ensure they’re properly tensioned. Keeping the machine’s software updated can significantly improve cutting quality and efficiency. Lastly, I recommend calibrating the machine periodically to maintain precision and accuracy in cuts. This attention to detail pays off in the quality of my projects.

CNCzone > Forum > Laser Engraving and Cutting Machines > Laser Engraving / Cutting Machine General Topics >. Thread: CO2 laser, PVC cutting? Page 1 of 2 1 2 …

Jul 29, 2024 … LaserPecker Support Center Help Center home page. Toggle … Step 2: Choose the Right Laser Cutting Machine for PVC Cutting. Here …

PVC Laser Cutting: 5 Steps to Success – LaserPecker Support Center

Laser Cutter Approved Materials. At SAIC we verify all material types for safety before allowing them to be cut on the laser cutters.

May 18, 2021 … I've accidentally cut a few things that I shouldn't have, and it happens. Hopefully the machine is ok long term!

[HELP] Accidentally laser engraved vinyl / pvc guitar pickguard….. : r …

Nov 23, 2023 … XTOOL M1 Review: the Best Desktop Laser Engraving and Blade Cutting Machine! … How to use the xTool M1 | How to Cut & Engrave on Basswood | How …

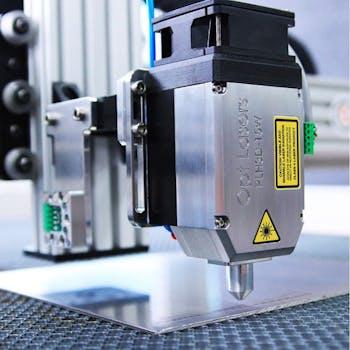

Understanding PVC Laser Cutting Machines

PVC laser cutting machines are essential tools in the arts and crafts world. These machines utilize high-powered lasers to precisely cut and engrave PVC materials, allowing for intricate designs that manual cutting simply can’t achieve. The versatility of PVC means I can create everything from shapes for scrapbooking to custom stencils for painting. The process is quick and efficient, reducing material waste and production time. Plus, using a laser cutter enhances the professional appeal of my projects. With the right settings, I can adjust the speed and power to suit different styles of work, which is an absolute game changer for any serious crafter.

Top Brands of PVC Laser Cutting Machines

A selection of brands that stand out for their quality and reliability in the PVC laser cutting machine market.

- Glowforge – I absolutely love how user-friendly Glowforge machines are. They make laser cutting accessible to everyone, from amateurs to seasoned pros.

- Epilog Laser – Known for their precision, Epilog Laser machines offer incredible detail. They are perfect for creating intricate designs in PVC.

- Trotec – Trotec machines are renowned for their speed and efficiency. They can handle large volumes of work without compromising quality.

- Boss Laser – Boss Laser strikes a great balance between affordability and performance. They’re particularly popular among small businesses and hobbyists.

- Full Spectrum Laser – Their range of machines caters to both hobbyists and professional users. Full Spectrum Laser machines also come with a robust community support system.

- Thunder Laser – I appreciated how Thunder Laser combines technology with affordability, making it a solid choice for smaller workshops.

- Gravotech – Gravotech specializes in engraving and cutting, providing durable laser machines that can tackle various materials, including PVC.

Benefits of Using a PVC Laser Cutting Machine

I appreciate the precision that a PVC laser cutting machine offers. With its ability to create intricate designs, I’ve found it invaluable for my arts and crafts projects. The speed of the cutting process greatly enhances my productivity. I can turn around multiple projects in a fraction of the time it would take with traditional methods. The versatility in cutting various thicknesses of PVC allows me to experiment freely. Plus, the clean edges mean less finishing work, allowing me to focus on creativity rather than cleanup.

Jul 26, 2016 … This allowed me to cut the length of my shelf at any … Large Scale Laser Cutting Machine specail for pvc stretch ceiling film cutting.

Common Applications of PVC Laser Cutting

PVC laser cutting opens up a world of exciting possibilities for creative projects. I often use this method to create custom signs and displays, as the precision and clean edges elevate the overall look. Craft enthusiasts can use PVC laser cutting for intricate designs in both 2D and 3D applications. From decorative wall art to personalized gifts, the versatility is unparalleled. I also experiment with making stencils and templates, which simplifies complex crafting tasks. Whether for home decor, business branding, or unique DIY projects, PVC laser cutting is a game changer.

Tips for Choosing the Right Laser Cutting Machine

First, know your material. Different machines excel with wood, fabric, or acrylic. Next, consider power and speed. Higher wattage means quicker cuts but can lead to burning materials if mismanaged. Don’t overlook software compatibility. Choose a machine that works well with the design software you use. Remember, size matters. Assess your workspace and project requirements before deciding on a machine. Finally, budget for ongoing maintenance; a machine is only as good as the care it receives.

Essential Safety Precautions

Taking risks in arts and crafts can lead to accidents. Here’s how to keep safe while being creative.

- Always wear appropriate protective gear. Whether it’s goggles for painting splatters or gloves for handling sharp tools, protect yourself first.

- Keep your workspace tidy and organized. Clear away clutter to prevent accidents; you want inspiration, not hazards.

- Use tools and materials as intended. Misusing a tool can lead to injuries, so read instructions and follow guidelines carefully.

- Be mindful of your surroundings. Ensure you have ample space to work without danger of knocking things over or getting tangled.

- Store hazardous materials properly. Keep paints, chemicals, and sharp instruments out of reach of children and pets to avoid accidents.

As an Amazon Services LLC Associates Program participant, we earn advertising fees by linking to Amazon, at no extra cost to you.

What materials can be cut with a PVC laser cutting machine?

A PVC laser cutting machine is excellent for various materials. You can cut PVC sheets, acrylic, and even some wood types. As a fan of crafts, I’ve found PVC particularly versatile for creating custom designs. It’s also effective with foam and certain types of leather, making it ideal for diverse projects. However, always check the machine specifications for compatibility, especially with thicker materials.

What are the safety measures I should take?

Always wear protective gear. Safety goggles, gloves, and aprons are non-negotiable when dealing with paints, glues, and tools. Be aware of your surroundings. Ensure your workspace is clutter-free to prevent accidents. If you’re using sharp objects or heat tools, always cut away from your body and keep your fingers clear. Follow product instructions carefully. Read labels on materials to avoid harmful reactions. Keep all crafts supplies out of reach of children and pets. Practicing these measures not only keeps you safe but also allows for a more enjoyable crafting experience.

How do I maintain my PVC laser cutting machine?

Regular maintenance is crucial for optimal performance. I clean the machine’s optics and mirrors frequently to prevent residue buildup that affects cutting quality. It’s also essential to check and tighten all mechanical components, as loose parts can lead to inaccuracies. Lubricate moving parts once a month; it reduces wear and enhances performance. Moreover, updating the software ensures compatibility with design files and improves functionality. Lastly, always keep the cutting bed clean to avoid any unwanted debris interfering with your projects.

Can I use a PVC laser cutter for small home projects?

Absolutely! Using a PVC laser cutter for small home projects can be incredibly rewarding. I’ve created everything from custom coasters to intricate wall art with mine. However, be cautious; PVC can release harmful fumes when cut. Always work in a well-ventilated area and consider using a fume extractor. Ensure your machine settings are optimized for PVC to avoid damaging the material or your machine. Also, start with simpler designs to get comfortable with the cutter’s capabilities.

What is the average cost of a PVC laser cutting machine?

The average cost of a PVC laser cutting machine varies significantly based on features and capabilities. Generally, entry-level machines can start around $2,000, while mid-range options often fall between $5,000 to $15,000. High-end, industrial-grade models can exceed $30,000. When considering a purchase, evaluating your specific needs and potential usage is crucial, as this influences your return on investment. Don’t just look at upfront costs; consider ongoing maintenance and operation expenses, too.

Regular maintenance is essential. I’ve seen how proper care can dramatically improve a machine’s durability. Skipping routine check-ups and cleaning leads to breakdowns and costly replacements.

PVC laser cutting machines offer unparalleled precision for crafters. This technology allows for intricate designs and clean edges, transforming ordinary projects into professional-looking masterpieces.

Safety is absolutely crucial when operating laser cutting equipment. The potential risks include severe burns, eye damage, and fire hazards. Prioritize the proper use of safety gear and equipment at all times.