As an Amazon Services LLC Associates Program participant, we earn advertising fees by linking to Amazon, at no extra cost to you.

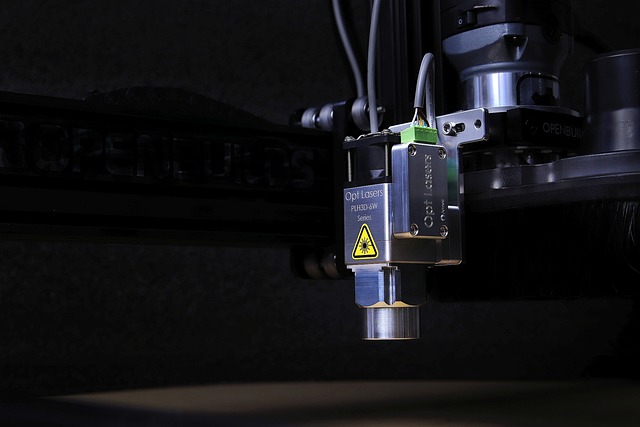

Maintaining Your Laser Engraving Equipment

Regular maintenance of your laser engraving equipment is crucial for optimal performance. I prioritize cleaning the lenses and mirrors to avoid residue build-up that affects the engraving quality. Periodically check the alignment to ensure precision in designs. Lubricating the moving parts prevents wear and tear, prolonging the life of the machine. I also recommend keeping the ventilation system clear of dust and debris to maintain effective airflow. Monitor the software for updates and potential bugs, as outdated software can hinder functionality. Finally, have a routine assessment schedule to catch issues before they escalate.

Step-by-Step Guide for a Beginner Project

This guide will walk you through creating a simple painting project, perfect for beginners eager to embrace their creativity.

- Gather Your Supplies: You’ll need a canvas, acrylic paints, brushes, a palette, and water. Having everything ready will keep the process smooth.

- Choose Your Painting Style: Decide whether you want to go abstract or representational. This choice sets the tone for your project.

- Sketch Your Design: Lightly outline your design on the canvas with a pencil. This will guide your painting and act as a foundation.

- Start with Background Colors: Apply lighter colors first, working from background to foreground. This technique helps create depth.

- Layer Your Paint: Allow each layer to dry before adding the next. This prevents colors from mixing unintentionally and maintains clarity.

- Add Details: Once the base colors are in place, use smaller brushes to add intricate details. This is where your painting comes to life.

- Step Back and Evaluate: Periodically look at your work from a distance. This gives a fresh perspective and helps identify areas needing adjustment.

- Finish with a Varnish: After your painting is dry, consider applying a protective varnish. This not only enhances colors but also preserves your artwork.

Common materials compatible with laser cutting

Here’s a rundown of popular materials you can effectively use with laser cutting technology.

- Acrylic: This clear plastic is versatile and offers a sleek finish, ideal for signage and crafts.

- Wood: Thin plywood or medium-density fiberboard (MDF) cuts beautifully, allowing for intricate designs.

- Paper: From cardstock to specialty paper, laser cutting creates precise shapes and details for various projects.

- Leather: This gives a unique texture and elegance to items like bags and accessories.

- Fabric: Lightweight materials can be cut with precision, great for appliqué and quilting endeavors.

- Cardboard: Economical for prototypes and crafts, it works well for functional models and decorations.

Creative Project Ideas for Wood Laser Engraving

I love transforming everyday items into artistic masterpieces using wood laser engraving. One of my favorite projects is creating personalized coasters. They make fantastic gifts and can be customized with initials or unique designs. Another idea is crafting intricate wall art. Choosing a meaningful quote or image and engraving it onto a wooden panel adds warmth to any space. Personalized cutting boards are also a hit, especially when engraved with family recipes or names. Lastly, I enjoy making engraved keychains, perfect for party favors or personalized gifts. The possibilities are endless with laser engraving!

Top Laser Engraver Brands to Consider

A look at some of the leading laser engraver brands known for their quality, performance, and support in the crafting community.

- Glowforge: I find Glowforge’s user-friendly interface incredibly appealing for beginners. It’s perfect for various projects, from intricate designs to basic engraving, and their support is top-notch.

- Epilog Laser: Epilog Laser machines are known for their durability and precision. I’ve used their products for professional projects, and the quality of the engravings always impresses me.

- Trotec: Trotec engravers are a bit on the pricier side, but the speed and efficiency they offer are unmatched. I’ve noticed a significant boost in my productivity with these machines.

- Orion Motor Tech: If you’re looking for an affordable option without sacrificing quality, Orion Motor Tech is a brand I often recommend. It’s reliable for hobbyists and small business owners alike.

- Dremel: Dremel’s laser engraver is compact yet powerful, making it an excellent choice for those tight on space. I’ve enjoyed using it for personal projects, achieving great results.

Choosing the Right Wood for Laser Projects

Selecting the appropriate wood is crucial for successful laser projects. I prefer birch plywood for its versatility—it’s easy to cut, engrave, and has a smooth finish that accepts paint and stains exceptionally well. MDF is also a solid choice due to its density, which offers clean cuts but lacks the natural grain. For those seeking a more rustic aesthetic, consider pine or oak; they engrave beautifully but can vary in density, affecting the final result. Ultimately, understanding the wood’s properties ensures you’re equipped for the best creative outcomes.

Dec 3, 2023 … Is your woodworking or CNC shop the type that needs a laser engraver or laser cutter, as well as a CNC machine? Watch this video to learn 5 …

Oct 23, 2021 … 1/4” with good quality wood. There a ton of cheap engravers; but they won't cut. You want a minimum of about 40 watts (assuming CO2).

Nov 20, 2023 … … laser engraver, or you want to laser engrave or laser cut wood, plastic or metal, you will find a great laser engraving machine for your …

I Tested the Best Laser Engravers and Cutters of 2023 (so you don’t …

Sep 18, 2022 … 30 votes, 14 comments. Hi, I have been looking around for things to do on my laser cutter/engraver and was wondering if there was a list of …

Is there a list of websites for cutting/engraving? : r/lasercutting

Aug 9, 2023 … Want to buy a laser engraver or laser cutter? Here are my top recommendations for any budget! The Laser Comparison Chart …

The Best Laser Engraver & Cutter to Get at ANY Budget – YouTube

Understanding Wood Laser Engravers and Cutters

Wood laser engravers and cutters are transformative tools in the crafting world. These machines use focused laser beams to precisely etch designs or cut through wood, allowing for intricate details that are hard to achieve by hand. The versatility makes them indispensable for hobbyists and professionals alike. Different types of wood respond uniquely to laser engraving, affecting the depth and quality of the finish. Understanding settings like power, speed, and frequency is crucial to mastering these tools. For anyone serious about woodworking projects, investing time in learning their operation pays off with remarkable, custom outcomes.

Safety precautions when using a laser engraver

Essential safety measures to take while operating a laser engraver.

- Always wear protective eyewear specifically rated for laser use.

- Keep your workspace well-ventilated to avoid fumes and smoke.

- Clear any flammable materials away from the engraving area.

- Never leave the machine unattended while it’s operating.

- Be aware of your machine’s emergency shut-off switch and know how to use it.

- Make sure all safety covers are in place before using the laser engraver.

Essential Tips for Successful Laser Engraving

Choose the right material. Different materials respond uniquely to laser engraving. I always get the best results with wood, acrylic, and metal. Test settings before committing. Each material requires different power and speed settings, so doing test engravings is a must. Design matters! Use clear vectors and avoid intricate details that might not translate well. Maintenance is key. Keep your laser cutter clean to ensure precision and longevity. Lastly, don’t forget about safety. Always wear safety glasses and ensure proper ventilation during engraving.

As an Amazon Services LLC Associates Program participant, we earn advertising fees by linking to Amazon, at no extra cost to you.

How does a laser engraver work?

A laser engraver operates by using a focused beam of light to etch designs onto various materials. The laser moves across the surface, which heats and vaporizes the material in precise patterns. This process allows for intricate designs that are often impossible to achieve with traditional engraving methods. It’s incredibly versatile, working effectively on wood, acrylic, metal, and more. The depth and intensity of the engraving can be adjusted by altering the speed and power of the laser, enabling a broad range of artistic expression.

What types of wood can be used for laser engraving?

Laser engraving works exceptionally well on various wood types, each providing unique finishes and textures. I find that birch plywood and maple are two of the best choices due to their smooth surfaces and consistent grain patterns. Cherry and walnut add a rich, warm tone, enhancing the contrast of the engravings. Basswood is also a popular option, especially for intricate designs. It’s important to avoid softwoods like pine for fine detail work because they tend to scorch and produce uneven engravings. Choosing the right wood impacts not just aesthetics but also the engraving’s clarity and quality.

What are the safety concerns with laser engraving?

Safety is critical when it comes to laser engraving. First, the laser itself can cause severe burns or eye injuries if proper protective eyewear isn’t worn. The fumes produced during the engraving process can be hazardous; always use adequate ventilation or a fume extractor. Additionally, materials like plastics can release toxic gases when engraved. Never leave the laser unattended, as fires can start if the material ignites. Always have fire safety equipment nearby, and keep your workspace organized to minimize the risk of hazards.

How do I troubleshoot common laser engraving issues?

First, check your settings. Ensure the power and speed are appropriate for the material. If the engravings are too light or not etching properly, adjust these settings. Next, inspect your lens and mirrors. Clean them regularly, as dirt can drastically affect performance. If the engraving looks uneven, verify the material is flat and secure. Lastly, test your software. Confirm that the design file is correctly configured; sometimes, minor glitches can lead to major errors in the engraving process.

Can I use a laser cutter for materials other than wood?

Absolutely, a laser cutter is versatile and can handle a variety of materials. You can effectively cut and engrave acrylic, leather, paper, and even some metals like stainless steel—with proper settings and focusing. However, each material requires specific settings to avoid damage. For example, acrylic needs a higher speed and lower power than wood for optimal results. Always check the safety precautions as well, as certain materials, like PVC, emit toxic fumes. Experimentation is key to mastering different materials, so don’t hesitate to push boundaries!

Laser engraving is a game changer in the world of arts and crafts. The accuracy it provides allows every detail to shine, while its versatility lets my creativity run wild.

**Choosing the right wood directly impacts engraving quality.** I’ve seen stunning results with softer woods like pine, while hardwoods often yield finer detail. **Don’t underestimate the significance of wood selection.**

Regular maintenance is essential for maximizing your laser cutter’s lifespan. Simple tasks like cleaning lenses and checking belts can prevent costly repairs and ensure consistent performance.