As an Amazon Services LLC Associates Program participant, we earn advertising fees by linking to Amazon, at no extra cost to you.

Safety Tips for Operating CNC Fiber Laser Cutters

Safety is non-negotiable. Operating CNC fiber laser cutters can be hazardous if proper precautions aren’t taken. Always wear protective eyewear to shield your eyes from harmful laser light.

Ventilation is key. Harmful fumes can accumulate quickly, so ensure your workspace is well-ventilated. Keep flammable materials away from the cutting area to prevent fires.

Training matters! Operators should be fully trained and familiar with emergency procedures. Regular safety drills can make a big difference.

According to Cameron Lee from ACCURL, “Safety is crucial in CNC operations; all standard protocols must be followed to prevent accidents.”

Most people think following basic safety protocols is enough. I believe integrating advanced technologies, like AI monitoring systems, can significantly improve safety. They can alert operators to potential hazards before they escalate.

Exploring new safety technologies can lead to a safer, more efficient work environment. Don’t just stick to the basics; innovate!

Exploring Alternative Cutting Techniques for Crafts

Most people think laser cutting is the ultimate solution for crafts. I believe hybrid cutting systems deserve a spotlight. They blend the best of laser and mechanical cutting, making them versatile for various materials.

For instance, using a waterjet alongside a laser can tackle thicker materials without warping. This combo opens up creative doors for artists, allowing for intricate designs without compromising quality.

Another approach involves exploring the potential of CNC routers for larger projects. They can handle larger sheets of material and intricate cuts, making them a fantastic alternative for specific craft needs.

As noted by Cameron Lee from ACCURL, “CNC laser cutting offers unprecedented speed, precision, and versatility in the manufacturing sector.” But let’s not forget about the power of combining techniques to maximize creativity!

Let’s embrace innovation and explore these alternatives. They might just be the key to unlocking your next masterpiece!

Advantages of Using Fiber Laser Cutters in Crafts

CNC fiber laser cutting is a dream for crafters! It offers unmatched precision and versatility. You can create intricate designs without breaking a sweat.

Many believe traditional cutting methods suffice. But I think fiber lasers are way better because they handle various materials seamlessly—think wood, acrylic, and even metals!

Another common opinion is that laser cutting is too complex. But honestly, with a little practice, it’s that simple. You’ll be amazed at what you can produce.

According to Cameron Lee from ACCURL, “The cost-effectiveness and exceptional accuracy of CNC laser cutting make it indispensable for the manufacturing sector.” That’s a fantastic point!

Consider hybrid systems too; they blend laser cutting with other methods. This opens up a world of possibilities for unique projects.

Don’t overlook safety! Always wear protective gear and ensure proper ventilation while cutting. Safety first, right?

Looking ahead, integrating AI into these machines could change the game. Imagine real-time adjustments for even better results!

Maintaining Your Fiber Laser Cutter for Optimal Performance

Here are some key points to keep your CNC fiber laser cutter running smoothly and efficiently.

- Regularly clean the lens and mirrors. This prevents dust buildup and maintains cutting quality.

- Check and adjust the focus regularly. Proper focus ensures precision in every cut.

- Monitor coolant levels and temperature. Keeping them in check prevents overheating and prolongs machine life.

- Inspect the cutting bed for wear. A flat bed is crucial for accurate cuts and material stability.

- Update software and firmware frequently. This helps in utilizing the latest features and fixes.

- Schedule regular maintenance with professionals. Experts can identify potential issues before they become costly problems.

- Keep a log of all maintenance activities. Tracking helps in identifying patterns and planning future upkeep.

Creative Applications for Fiber Laser Cutting

Fiber laser cutting isn’t just for industrial use; it’s a crafty tool for artists like us! I’ve seen stunning wall art created from intricate laser-cut designs. Imagine transforming your sketches into precise wooden pieces or acrylic displays. It’s that simple!

Many think fiber lasers are limited to metalwork, but I believe they can cut through materials like leather and even fabric. This opens up endless possibilities for unique fashion items or home decor.

Most people assume laser cutting is just for pros, but I think DIY enthusiasts can easily dive in. With the right setup, you can create personalized gifts or custom pieces for your craft projects. The versatility is mind-blowing!

As for safety, it’s vital to follow guidelines. But with proper precautions, the creative potential is worth it. According to Cameron Lee from ACCURL, “CNC laser cutting offers unprecedented speed, precision, and versatility in the manufacturing sector.”

Exploring new materials is exciting too! Why not experiment with composite materials? They can add a unique touch to your projects.

Common Mistakes to Avoid When Using a Fiber Laser Cutter

Avoiding these common pitfalls can greatly enhance your fiber laser cutting experience and results.

- Not adjusting the settings for different materials. Each material needs specific power and speed settings.

- Ignoring safety precautions. Always wear protective eyewear and ensure proper ventilation.

- Skipping maintenance checks. Regularly inspect your machine to prevent unexpected breakdowns.

- Overloading the cutting bed. Too many materials can lead to uneven cuts and machine strain.

- Neglecting to test cuts. Always perform test cuts on scrap material to fine-tune your settings.

- Using dull lenses. A clean and sharp lens is crucial for optimal cutting performance.

- Forgetting to keep the workspace organized. A cluttered area can lead to accidents and inefficiencies.

- Rushing the process. Take your time to set everything up correctly for the best results.

- Not considering the thickness of materials. Different thicknesses require different approaches and settings.

- Failing to document successful settings. Keep a record of what works for easy reference in future projects.

Meet your diverse cutting needs with our industrial laser cutting machine, CNC fiber laser cutting machine. onsite installation plus training. Get a quote!

Discover our fiber laser cutters and find the product suited for your business. For every fiber laser cutting technology we have studied different products.

Oct 6, 2020 … Overbuild, the cutting heads are heavy. You can see table and bearing specs at any of the large manufacturers websites like Boss or Piranha.

I want to make a Fiber laser CNC. At least 750w. I have time and …

Laguna CBX fiber laser cutting system designed and optimized for quick and … site. Cookies Policy. Got It!

DIY Fiber Laser Tube Cutting Machine | Part 3: Rear Chuck. 6.5K views. 2 … DIY Fiber Laser Cutter 1000w: First Test Cut. 36K views. Ultimate Bee 1000 x …

Materials Suitable for CNC Fiber Laser Cutting

Here’s a quick rundown of materials that work perfectly with CNC fiber laser cutting. Each material has its unique properties, making it suitable for various projects.

- Mild Steel: This is a go-to for many projects. It’s affordable and cuts like butter.

- Stainless Steel: Perfect for durable applications. It resists corrosion, making it ideal for outdoor use.

- Aluminum: Lightweight and strong. It’s great for intricate designs due to its malleability.

- Copper: A bit tricky but doable! It reflects laser light, requiring specific settings.

- Acrylic: This plastic shines when cut with lasers. It leaves smooth edges and is perfect for signage.

- Wood: Cuts beautifully and adds a natural touch to projects. Just watch for burning!

- Textiles: Yes, you can cut fabrics! It opens up creative avenues for fashion and home decor.

- Composites: These materials are gaining traction. They offer strength without added weight, perfect for aerospace.

- Plastics: Various types can be cut, but some may warp. Always test settings first.

Understanding CNC Fiber Laser Cutters

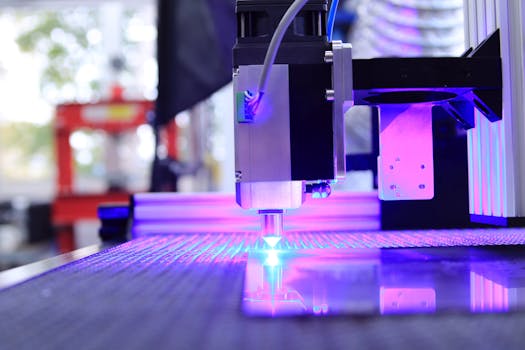

CNC fiber laser cutters are some of the most precise tools in crafting today. They use a focused laser beam to slice through materials with incredible accuracy. It’s that simple! I love how they can cut everything from wood to metal without changing tools.

Many people think fiber lasers are just for industrial use. I believe they are perfect for crafts too! They allow us to create intricate designs that would be hard to achieve otherwise.

According to Cameron Lee from ACCURL, “CNC laser cutting offers unprecedented speed, precision, and versatility in the manufacturing sector.” This versatility is a game changer for artists and crafters.

Some folks stick to traditional cutting methods, but I think hybrid systems that combine laser cutting with other techniques can open up new creative possibilities. Imagine the potential!

It’s crucial to stay updated on the latest advancements in laser cutting technology. Exploring material optimization techniques could greatly enhance our crafting experience.

Key Features of CNC Fiber Laser Cutters

Here’s what makes CNC fiber laser cutters so special:

- High Precision: These machines cut with extreme accuracy, leaving clean edges.

- Versatility: They handle various materials, from metals to plastics effortlessly.

- Speed: Fiber lasers operate faster than traditional cutters, boosting productivity.

- Low Operating Costs: They consume less energy and require minimal maintenance.

- Minimal Waste: Precision cuts mean less material is wasted, saving money.

- User-Friendly: Modern CNC systems are intuitive, making them accessible for beginners.

As an Amazon Services LLC Associates Program participant, we earn advertising fees by linking to Amazon, at no extra cost to you.

What materials can be cut with a CNC fiber laser cutter?

I’ve seen CNC fiber laser cutters work wonders on various materials! They can effortlessly slice through metals like mild steel, stainless steel, and aluminum. Acrylic and wood? No problem! The precision is just mind-blowing.

Most people think you can only cut standard materials, but I believe exploring niche applications is key. Some advanced systems can even handle complex composites and textiles. Imagine the creative possibilities in crafts!

As Cameron Lee from ACCURL said, “Fiber lasers can handle a variety of materials, including reflective ones, with improved effectiveness.” It’s that simple—your options are vast!

For those wanting to push boundaries, consider experimenting with unique materials. The right settings can lead to stunning results!

How does a CNC fiber laser cutter work?

A CNC fiber laser cutter operates by directing a high-powered laser beam onto the material. The laser beam melts or vaporizes the material along the predetermined path.

This process is controlled by computer software, which ensures precision. It’s that simple!

Most people think that CNC laser cutting is all about the laser. But I believe the software’s role is equally crucial, as it dictates the efficiency and accuracy of the cuts.

According to Cameron Lee from ACCURL, “CNC laser cutting offers unprecedented speed, precision, and versatility in the manufacturing sector.”

Exploring alternative cutting methods, like hybrid systems, can sometimes yield better results for specific projects. They combine laser cutting’s precision with other techniques, enhancing versatility.

In the future, integrating AI into CNC systems could lead to real-time optimization and smarter cutting strategies. This innovation is something to watch!

What safety equipment is needed when using a fiber laser cutter?

Safety gear is a must when using a CNC fiber laser cutter. Protective eyewear is essential to shield your eyes from harmful laser light. No way you’d want to risk that!

Respirators or masks are crucial too. They help filter out harmful fumes generated during cutting. Proper ventilation can make a world of difference.

Fire safety gear, like extinguishers, should always be nearby. Being prepared is better than dealing with a fire emergency!

According to Cameron Lee from ACCURL, “Safety is crucial in CNC operations; all standard protocols must be followed to prevent accidents.” So, gear up and stay safe!

CNC fiber laser cutting is a total game changer! It provides unmatched precision for intricate designs. I can create stunning crafts without worrying about rough edges.

Many people think laser cutting is only for industrial use. But I believe it’s perfect for DIY projects, too! Imagine cutting detailed patterns in wood or acrylic for your next craft.

According to ACCURL, “CNC laser cutting offers unprecedented speed, precision, and versatility in the manufacturing sector.” This means we can achieve professional results at home.

Plus, I love that I can work with various materials effortlessly. From metals to plastics, the possibilities are endless!

We should also explore hybrid cutting systems that combine laser and waterjet techniques. This approach could unlock even more creative potential in our projects.

Operating CNC laser cutting machines demands serious attention to safety. Protective eyewear is a must! Direct or reflected laser light can cause severe eye damage. Proper ventilation is essential to minimize inhaling harmful fumes.

It’s that simple: keep flammable materials away from the cutting area. Training is non-negotiable. Operators should know emergency protocols and machine manuals inside out to handle any accidents.

Most people think standard safety procedures are enough, but I believe integrating advanced safety technology is key. AI monitoring systems and remote operations can significantly elevate safety standards. It’s time to rethink how we approach safety in CNC laser cutting!