As an Amazon Services LLC Associates Program participant, we earn advertising fees by linking to Amazon, at no extra cost to you.

Exploring Alternative Approaches to Metal Cutting

Most people believe that coil fed laser cutting is the only way to achieve efficiency. I think a semi-automated system might be better because it allows for flexibility in custom jobs. This setup combines the best of both worlds—speed and adaptability.

Many assume traditional methods are outdated. But I argue they still hold value for bespoke projects where unique designs are crucial. Embracing a hybrid approach could cater to both high-volume production and one-off creations.

According to Baison Laser, “Automation plays a huge role in optimizing your factory operations.” But I feel that over-reliance on automation might stifle creativity. Balancing automation with manual techniques can lead to innovative outcomes.

New topics like the integration of AI in coil fed systems are gaining traction. This could redefine how we approach metal cutting, enhancing precision and reducing waste.

Oct 8, 2016 … The second great advantage of coil fed lines is the higher production speed. In particular, today's punching and fiber laser cutting machines …

Punching and laser cutting from coil: how to generate 197.400 Euro …

Advantages Over Traditional Cutting Methods

Coil fed laser cutting machines are a total win over traditional methods! Most folks think traditional methods are the best for all jobs, but I strongly disagree. Why? Because coil fed systems automate the process, making it faster and way more efficient.

These machines cut down on manual labor, which means less tired workers. Imagine cutting complex shapes with less material waste! That’s what coil fed laser cutting does. It optimizes material usage like a pro.

Not to mention, the precision is on another level. According to Baison Laser, “Coil-fed systems greatly reduce the loading and unloading time of raw material.” That’s huge for productivity!

Some might argue that traditional systems work better for custom jobs. Sure, but I believe the flexibility of coil fed systems can adapt quickly to various designs. Why settle for less efficiency when you can have it all?

Let’s not forget about the future! The integration of AI in these systems could take efficiency to new heights. It’s an exciting time for innovation in metal cutting!

The heart of the laser blanking system is a proven TruLaser cutting machine. The coil material is transported linearly through the machine, significantly …

DIMECO designed his new LINACUT® concept combining the unmatched flexibility of laser cutting together with the performance of Dimeco coil fed processes.

The automatic coil–fed and sheets fed laser cutting machine from laser cutting blanking line has the most versatile setup.It processes with the maximum …

RDI's Coil–Fed Laser Blanking technology enables manufacturers to continuously cut parts direct from metal coils while eliminating flashback.

FAGOR ARRASATE´s laser blanking system combines a fiber laser cutting machine with an automatic metal coil feeding system, resulting in an efficient coil …

Impact of Automation on Laser Cutting Processes

Automation in coil fed laser cutting is reshaping the manufacturing landscape. Here are some insights on its impact:

- Automation streamlines production. It reduces human error and speeds up workflows.

- Real-time monitoring enhances quality. Sensors ensure every cut meets specifications without manual checks.

- Cost savings are significant. Less labor and reduced waste translate to lower operational expenses.

- Flexibility is key. Automated systems can adapt to various designs quickly, accommodating market demands.

- Predictive maintenance minimizes downtime. AI can forecast issues before they disrupt production, keeping everything running smoothly.

- Enhanced precision is a game-changer. Automated systems achieve accuracy that manual methods struggle to replicate.

Creative Projects Using Coil Fed Laser Technology

Explore innovative ways to leverage coil fed laser cutting technology in artistic projects. These ideas can inspire DIY enthusiasts and professionals alike to create unique pieces.

- Cut intricate designs for custom metal wall art. It’s that simple and adds flair to any space.

- Create personalized jewelry pieces. The precision of laser cutting allows for detailed engravings.

- Design unique home decor items like lampshades or decorative panels. Use various materials for stunning effects.

- Produce custom signage for businesses or events. Laser cutting ensures clean edges and professional finishes.

- Make bespoke furniture components. This technology can transform ordinary pieces into works of art.

Key Components of a Coil Fed Laser Cutting System

Here are the essential components that make coil fed laser cutting systems tick. Each part plays a critical role in ensuring smooth operations and high-quality outputs.

- Decoiler: This device unwinds the metal coil, feeding it into the cutting machine for seamless operation.

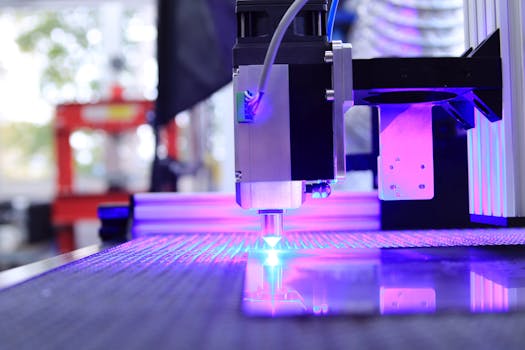

- Laser Cutting Head: This is where the magic happens! It precisely cuts the material based on programmed designs.

- Sheet Metal Straightener: Ensures the metal is flat before cutting, preventing errors and enhancing quality.

- Control System: This brain of the operation manages everything, ensuring the cutting process runs smoothly and efficiently.

- Sensors: These monitor the cutting process in real-time, allowing for immediate adjustments to maintain quality.

Innovative Applications in Arts and Crafts

Coil fed laser cutting isn’t just for factories; it’s a treasure for artists too! Imagine creating intricate designs in metal with ease. This technology opens doors to unique projects.

Most people think laser cutting is only for mass production. But I believe it’s perfect for custom art pieces. You can craft everything from stunning sculptures to personalized home decor.

Many assume these machines are too complex for small-scale artisans. However, semi-automated systems can offer flexibility and creativity. They adapt to various designs without sacrificing speed!

According to Baison Laser, “Coil-fed laser cutting is ideal for any industry that relies on large-volume production of flat metal parts.” But I see it as a way to elevate art. It’s that simple!

Exploring new trends like integrating AI can further enhance artistic capabilities. Imagine a future where your designs are not only precise but also smarter!

Understanding Coil Fed Laser Cutting Machines

Coil fed laser cutting machines are a marvel of modern technology. They automate the process of cutting sheet metal from coils, making it faster and more precise. I love how they streamline production; it’s that simple!

Most people think traditional methods are still the best. But I believe coil fed systems are the future because they minimize manual labor and drastically reduce waste. According to Baison Laser, “Coil-fed systems greatly reduce the loading and unloading time of the raw material.”

These machines are equipped with advanced sensors for real-time monitoring. This means fewer errors and higher quality output. Just imagine the possibilities!

For those looking for flexibility, semi-automated systems blend manual and automated processes. They adapt quickly to custom jobs, offering a unique balance between speed and personalization.

New technologies are on the horizon, too. The integration of AI in these systems can optimize production and enhance diagnostics. It’s an exciting time for metal fabrication!

Top Benefits of Using Coil Fed Laser Cutting

Discover the standout advantages of coil fed laser cutting that can transform your metalworking projects.

- Speedy Production: Coil fed systems drastically cut production time. You can churn out parts faster than traditional methods.

- Less Waste: This method optimizes material usage. You’ll see a significant reduction in scrap metal.

- Precision Cutting: Enjoy clean, burr-free edges. This means less post-processing work for you.

- Reduced Labor Costs: Automation minimizes manual handling. This leads to lower labor expenses overall.

- Versatility: These machines adapt well to various industries. From automotive to arts, they can do it all.

- Continuous Operation: Fully automated systems allow for non-stop production. This boosts your overall efficiency.

- Enhanced Safety: Fewer manual operations mean less risk of injury. Safety is a major plus in any workshop.

- Real-Time Monitoring: Advanced sensors provide instant feedback. You can maintain quality control effortlessly.

The Future of Coil Fed Laser Cutting Technology

Most people think coil fed laser cutting is just about efficiency. I believe it’s about creativity and customization. This technology opens up new avenues for artists and designers.

Imagine using coil fed systems to create intricate metal art pieces. It’s that simple! These machines can handle complex designs without compromising on speed.

Many assume automation limits creativity. I think it enhances it because artists can focus more on design rather than manual processes. According to Baison Laser, “Automation plays a huge role in optimizing your factory operations.” This applies to creative projects too.

Furthermore, integrating AI into these systems could redefine what’s possible. Predictive maintenance and real-time adjustments can lead to flawless creations. This isn’t just about cutting metal; it’s about pushing boundaries.

In conclusion, coil fed laser cutting isn’t just a tool for industries. It’s a game-changer for artists, offering endless possibilities for innovation.

As an Amazon Services LLC Associates Program participant, we earn advertising fees by linking to Amazon, at no extra cost to you.

What are the main components of a coil fed laser cutting system?

The main components of a coil fed laser cutting system are pretty straightforward. You have the decoiler, which feeds the sheet metal coil into the machine. Then there’s the laser cutting head, responsible for the actual cutting.

Don’t forget the sheet metal straightener! It ensures the material is flat before cutting. Lastly, the control system manages the entire operation, making everything run smoothly.

Each part plays a crucial role in enhancing productivity and precision. It’s that simple!

According to Baison Laser, “The decoiler is a larger rotating device that unwinds the sheet metal coil and feeds it to the laser cutting system.”

How does coil fed cutting benefit small-scale artisans?

Many think coil fed laser cutting is only for big manufacturers. But I believe it can be a game changer for small-scale artisans too. It allows for precision and speed in creating intricate designs without the hefty costs of traditional methods.

With coil fed systems, artisans can produce custom pieces quickly. No way! It minimizes material waste, letting creators focus on their art rather than scraps.

Some argue that traditional methods offer better flexibility for small batches. However, I think the efficiency of coil fed machines actually fosters creativity by allowing rapid prototyping and adjustments.

As noted by Baison Laser, “Coil-fed laser cutting is ideal for any industry that relies on large-volume production of flat metal parts.” This means artisans can scale their projects without sacrificing quality!

What is coil fed laser cutting?

Coil fed laser cutting is a method where a continuous coil of sheet metal feeds into a laser cutting machine. It’s super efficient! This process minimizes manual labor and speeds up production. You get precision cuts with less waste.

Many think traditional sheet fed systems are better for custom jobs. But I believe coil fed systems are more versatile because they handle high volumes and complex designs effortlessly. Automation is a game changer here! It reduces setup times and enhances productivity.

According to Baison Laser, “Coil-fed systems greatly reduce the loading and unloading time of the raw material.” This means more time for creativity and less on logistics.

For those in arts and crafts, this technology opens doors to unique designs and intricate projects. Imagine using coil fed cutting for custom metal art! It’s that simple.

Can coil fed laser cutting be used for custom designs?

Most people think coil fed laser cutting is just for mass production. But I believe it’s perfect for custom designs too! It’s that simple because the technology allows for intricate cuts and shapes without the hassle of traditional methods.

Imagine creating unique art pieces or personalized components. The precision of coil fed systems means you can achieve stunning results. Plus, the reduced material waste is a huge bonus.

Some might argue that traditional methods are better for custom jobs. However, I think coil fed laser cutting offers flexibility that can adapt to various design needs efficiently. It’s a win-win!

As noted by Baison Laser, “Coil-fed laser cutting is ideal for any industry that relies on large-volume production of flat metal parts.” That’s true, but it doesn’t stop there. This technology opens doors for artists and craftsmen to explore their creativity.

How does automation improve the coil fed laser cutting process?

Most people think automation just speeds things up. I believe it transforms entire workflows. Automated systems reduce human error and increase precision, making every cut flawless.

For example, with real-time monitoring, machines adjust settings on the fly. This ensures optimal performance and minimizes downtime. According to Baison Laser, “Automation plays a huge role in optimizing your factory operations.”

Many assume manual setups are still needed. But I think fully automated systems can handle complex designs effortlessly. They adapt quickly, allowing for rapid production without sacrificing quality.

While some argue for semi-automated systems, I feel that the future is fully automated. They offer unmatched efficiency and consistency. This is the way forward for any serious manufacturer.

Most people think manual labor is unavoidable in metal cutting. But I believe coil fed laser cutting changes that game. It automates processes, slashing labor needs and speeding things up.

Imagine cutting metal without the hassle of handling large sheets. It’s that simple! This method optimizes efficiency and lets artisans focus on creativity.

According to Baison Laser, “Coil-fed laser cutting is ideal for any industry that relies on large-volume production of flat metal parts.” That’s a big win for anyone in the arts and crafts scene!

Alternative approaches? Many still rely on traditional methods for custom jobs. But why not blend both? Semi-automated systems can offer flexibility and speed, catering to unique designs while keeping production flowing.

Future topics? The integration of AI in coil fed systems could be revolutionary. Imagine machines predicting maintenance needs or optimizing cuts in real time!

Many believe traditional cutting methods are the most efficient. I think coil fed laser cutting is way better because it optimizes material usage, reducing waste significantly. Less waste means more savings!

With precise cutting, you can create complex shapes while using fewer materials. It’s that simple! According to Baison Laser, “Coil-fed laser cutting is ideal for any industry that relies on large-volume production of flat metal parts.”

Plus, the automation in these systems minimizes handling, keeping everything neat and tidy. Why stick with old methods when innovation is here?

Most people think automation just speeds things up. I believe it’s about precision too. Automated systems in coil fed laser cutting mean less human error and more consistent results.

Imagine setting up a job with a few clicks. It’s that simple! You get your designs done faster and cleaner.

According to Baison Laser, “Automation plays a huge role in optimizing your factory operations.” This isn’t just about cutting time; it’s about cutting costs too.

Some might argue that traditional methods work fine. But I think they miss out on the benefits automation brings. Less waste, fewer mistakes, and a smoother workflow are just a few perks!

Let’s not forget about the integration of AI in these systems. It’s a game changer for diagnostics and maintenance, keeping everything running smoothly.

So, if you’re still on the fence, consider this: automation isn’t just a trend; it’s the future of efficient manufacturing.