As an Amazon Services LLC Associates Program participant, we earn advertising fees by linking to Amazon, at no extra cost to you.

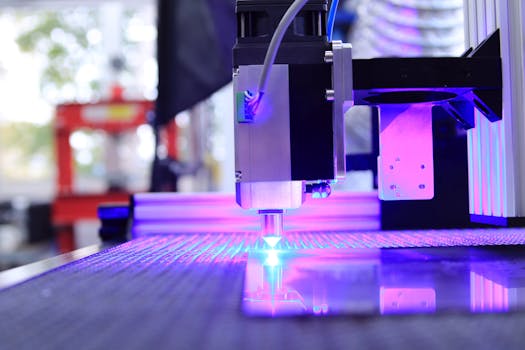

Tips for Designing with Laser Cutting

Prioritize materials that laser cutters can easily process. Choose options like acrylic, wood, or cardboard to achieve clean cuts and intricate designs. Consider the thickness of your materials. Thicker materials require more power but can limit detail, while thinner materials allow fine intricacies. Utilize vector-based graphics software. SVG or CAD files are best, ensuring precise cuts and engravings. Be mindful of raster settings for engravings; too high can burn the material. Scale your designs appropriately. Always test your designs with less expensive materials before committing to the final product.

Safety Precautions When Using Laser Cutters

Essential safety practices for laser cutter users to keep in mind.

- Always wear appropriate personal protective equipment (PPE), such as safety goggles, to shield your eyes from harmful laser light.

- Ensure your work area is well-ventilated to prevent the buildup of harmful fumes from materials being cut.

- Keep a fire extinguisher nearby—combustible materials can ignite during laser cutting.

- Stay focused and avoid distractions while operating the laser cutter to prevent accidents.

- Never leave the laser cutter unattended while it’s in operation; monitor the process closely.

- Familiarize yourself with the machine’s manual and safety features before use

Jun 1, 2023 …Laser–cut jewelry can be created using a variety of materials, including: 10. Metals: Laser cutting machines can work with various metals, such …

Lasers & Jewelry: Revolutionizing Contemporary Jewelry Design

How to Choose the Right Laser Cutting Machine

First, consider what materials you’ll be working with. Some machines cut wood and acrylic, while others can handle metals. Next, think about the size of your projects. A larger work area may be necessary for expansive designs. Evaluate your budget. There are affordable options that still deliver quality, but don’t compromise too much on the core features. Finally, read reviews and join forums. Experiences from other crafters can significantly guide your choice, making sure you invest in a machine that fits your creative needs.

Key Features to Look for in a Laser Cutting Machine

When choosing a laser cutting machine, certain features stand out as essential for enhancing your creative projects.

- Power and Speed: Opt for machines with adjustable power settings to handle various materials effectively.

- Bed Size: A larger bed size allows for versatile project dimensions and accommodates bigger materials.

- Software Compatibility: Ensure the machine works seamlessly with your preferred design software for smoother operations.

- Cooling System: A reliable cooling system prevents overheating, ensuring consistent quality during extended use.

- User-Friendly Interface: An intuitive interface simplifies operation, making it easier for both beginners and seasoned users.

Maintaining Your Laser Cutting Machine

Regular maintenance is essential to keep your laser cutting machine in peak condition. I consistently check the optics and lenses for dust or residue, ensuring clean cuts and optimal performance. Lubrication of moving parts is another crucial step. I use machine-grade lubricants to prevent wear and tear. Additionally, I replace the air assist nozzle and filters regularly to maintain proper airflow, minimizing smoke buildup. Keeping software up to date is vital for efficiency and compatibility. I schedule routine checks and cleaning sessions, which not only extend the machine’s lifespan but also enhance my creative projects.

Popular Laser Cutting Projects for Jewelry

Exploring popular laser cutting projects for jewelry unveils endless creative possibilities. Here are some standout ideas.

- Customized Name Necklaces: I absolutely love making personalized name necklaces. It’s a fantastic way to let someone wear something uniquely theirs, and the clean cuts from the laser make each piece look exquisite.

- Intricate Earrings: Designing delicate earrings with intricate patterns is one of my favorite projects. The precision of laser cutting enables me to create stunning designs that would be too detailed for traditional methods.

- Engagement Rings: I can’t get enough of crafting custom engagement rings through laser cutting. The ability to incorporate intricate designs and personal touches is often a conversation starter and a genuine representation of love.

- Cuff Bracelets: My experiments with cuff bracelets have led to unique statements that blend modern aesthetics with personal significance. The flexibility in design makes it a rewarding challenge.

- Charms and Pendants: I adore creating themed charms and pendants. They are perfect for giving as gifts or adding a personal touch to any jewelry collection. The laser cutter allows for high detail without sacrificing strength.

Best Laser Cutting Machines for Beginners

Here are some top picks for beginner-friendly laser cutting machines that fit various budgets and project needs.

- Glowforge Basic: I love the Glowforge Basic for its intuitive design and ease of use. It’s perfect for crafting projects with its impressive precision and versatile materials like wood and acrylic.

- Epilog Zing: The Epilog Zing is a solid option for those ready to upgrade their game. It provides excellent engraving and cutting capabilities, making it great for more intricate projects.

- Orion Motor Tech 40W: This budget-friendly machine is fantastic for beginners. The Orion Motor Tech 40W is a reliable entry point into laser cutting, ideal for simple designs and quick projects.

- Silhouette Alta: The Silhouette Alta stands out for its compact size. Perfect for small projects, I appreciate its support for a variety of materials and beginner-friendly software.

- Full Spectrum Laser Muse: This one is a game-changer with its powerful capabilities and user-friendly interface. The Full Spectrum Laser Muse is exceptional for those wanting professional quality in their home setup.

Advantages of Using Laser Cutting in Jewelry Design

Laser cutting offers precision that traditional methods simply can’t match. This accuracy allows me to create intricate designs and detailed patterns with ease. I love how laser cutting minimizes waste, maximizing every inch of material. Speed is another major advantage; I can produce pieces quickly without sacrificing quality. The ability to customize designs is unparalleled, enabling me to bring my unique vision to life effortlessly. Moreover, the clean edges produced by laser cutting often require little to no finishing work, saving me valuable time. This technology truly transforms my approach to jewelry design.

… Laser Module (metal & wood) DIY Jewellery. HelenaDaydreamer · 9:00 · Making Jewelry & Gifts with xTool D1 Pro 20w Laser Cutting Machine. HelenaDaydreamer.

Feb 10, 2022 … here is an interesting site on laser cutters snd terminology … I have a hobby laser cutting and engraving machine and have heard of the …

Engraving/Cutting Machine – Jewelry Discussion – Ganoksin Orchid …

Jewellery making * Laser cutting/engraving * Arts & Crafts …more …more etsy.com/uk/shop/HelenaDaydreamerand 4 more links. Subscribe.

Feb 8, 2021 … I am looking at starting my own bespoke jewellery business and want to cut/create in house. Mainly names and shapes for necklaces/pendants/earrings etc.

Our gold laser cutting machine with a cutting accuracy of less than 0.02mm.The price of machines is very popular among jewelers.

Common Materials for Laser Cutting Jewelry

Acrylic is one of my favorite materials for laser cutting jewelry due to its versatility and vibrant colors. It’s lightweight, easy to work with, and offers a polished finish that really catches the eye. Wood can also create stunning pieces, especially when you choose varieties like bamboo or walnut. The natural grain adds a unique touch. Don’t overlook metal; stainless steel and aluminum offer durability and an industrial aesthetic. They can be surprisingly lightweight and maintain their form beautifully. Lastly, leather provides a softer, more organic feel, making it perfect for unique statement pieces. Each material brings its own charm and possibilities!

As an Amazon Services LLC Associates Program participant, we earn advertising fees by linking to Amazon, at no extra cost to you.

What types of materials can be cut using a laser cutter?

Laser cutters are incredibly versatile and can handle a variety of materials. I’ve successfully used them on wood, acrylic, paper, fabric, and leather. Each material reacts differently; for instance, wood gets clean, precise cuts, while acrylic can yield stunning edges. Metal is also an option but requires more powerful lasers. I’ve seen excellent results with anodized aluminum and thin sheets of stainless steel. Remember to always check the manufacturer’s guidelines for specific materials and settings. This ensures safety and optimal results in your projects.

How much does a laser cutting machine for jewelry cost?

A laser cutting machine for jewelry typically ranges from $2,000 to over $20,000. The price largely depends on features, brand, and size. Entry-level models are more affordable, suitable for hobbyists. However, if you’re serious about your craft and planning to produce professionally, spending on a mid-range to high-end machine is crucial for quality and ease of use. Investing wisely in a reliable machine can significantly enhance your creative output. Be sure to consider additional costs like software, maintenance, and materials.

What software is needed for laser cutting designs?

For laser cutting, vector graphic software is crucial. I highly recommend Adobe Illustrator and CorelDRAW, as they are industry standards that offer superior precision and control. Additionally, free options like Inkscape work well for simple projects. These programs allow you to create and manipulate designs effectively, ensuring compatibility with most laser cutters. Make sure to check the software’s export settings to confirm it supports the file types required by your laser cutting machine.

Is laser cutting safe for home use?

Safety in laser cutting at home isn’t trivial. I believe it requires a significant commitment to understanding the equipment and its usage. You must ensure proper ventilation, as fumes and smoke can be harmful. Protective eyewear is essential; never look directly at the laser beam. Additionally, maintaining a safe workspace free of flammable materials is crucial. Investing in a quality, well-reviewed laser cutter can significantly impact safety. Always follow manufacturer guidelines and local regulations, and if you’re unsure about any aspect, don’t hesitate to seek guidance. Your creativity shouldn’t come at the cost of safety.

What are the common mistakes to avoid in laser cutting jewelry?

One major mistake is not testing your settings on scrap material. This can lead to burned or uneven cuts that ruin your piece. Ignoring material compatibility is another blunder. Different materials react differently to laser cutting, and using the wrong one can result in disaster. Skimping on safety measures can cause serious issues. Always use proper goggles and keep flammable materials away. Lastly, neglecting post-processing steps can diminish the final quality. Make sure to clean edges and finish surfaces to achieve a polished look.

Laser cutting brings unparalleled precision and allows for intricate designs in jewelry making. I find it empowering to transform ideas into unique pieces with such accuracy and detail.

Choosing the appropriate machine is essential for successful crafting. The right tools enhance precision and ease, making your creative process smoother and more enjoyable.

Regular maintenance is crucial; it dramatically prolongs your laser cutter’s life. Simple tasks like cleaning optics and checking for alignment can prevent major issues and costly repairs.