As an Amazon Services LLC Associates Program participant, we earn advertising fees by linking to Amazon, at no extra cost to you.

Tips for Choosing the Right Laser Machine

When it comes to choosing the right laser machine for your arts and crafts projects, it can be overwhelming with so many options available. As a seasoned crafter myself, I know the importance of selecting the right tool for the job. Whether you’re a beginner or a seasoned pro, consider these important factors before making your decision. From power and precision to size and compatibility, each aspect plays a crucial role in finding the perfect fit for your creative endeavors. Don’t rush the process, take your time to research and test out different models to ensure you make an informed investment. Remember, the right laser machine can truly unlock your artistic potential and take your crafts to the next level. Happy crafting!

Factors to consider when purchasing a laser machine

When looking to invest in a laser machine for your arts and crafts projects, there are several key factors to keep in mind. Here are some important points to consider before making a decision:

- Budget: Determine your budget range and find a laser machine that offers the best value for your money.

- Power and speed: Consider the power and speed capabilities of the laser machine to ensure it can handle the type of materials and projects you plan to work on.

- Size and portability: Think about the size of the machine and whether you need it to be portable or stationary based on your workspace and project needs.

- Ease of use: Look for a laser machine that is user-friendly and comes with intuitive software for smooth operation.

- Safety features: Prioritize safety by choosing a machine with built-in safety features such as protective shields and emergency stop buttons.

- Customer support: Research the manufacturer’s customer support reputation to ensure you will have assistance if needed during setup or troubleshooting.

Advantages of laser cutting technology

As a crafting enthusiast, I have discovered the amazing benefits of laser cutting technology. Here are some key advantages that have truly revolutionized the way I approach arts and crafts:

- Precision: Laser cutting allows for incredibly precise cuts, ensuring clean edges and intricate designs.

- Versatility: From wood and acrylic to fabric and paper, laser cutting can work with a wide range of materials for endless creative possibilities.

- Speed: Say goodbye to hours of manual cutting! Laser cutting technology works quickly and efficiently, saving valuable time on your projects.

- Repeatability: With laser cutting, you can easily replicate the same design multiple times with consistent results, perfect for handmade products or gifts.

- Minimal waste: The precise nature of laser cutting means minimal material wastage, making it a more sustainable option for eco-conscious crafters.

- Intricate details: Laser cutting technology can create intricate and detailed designs that would be challenging to achieve by hand, adding a professional touch to your projects.

Benefits of Using a Laser Machine for Metal

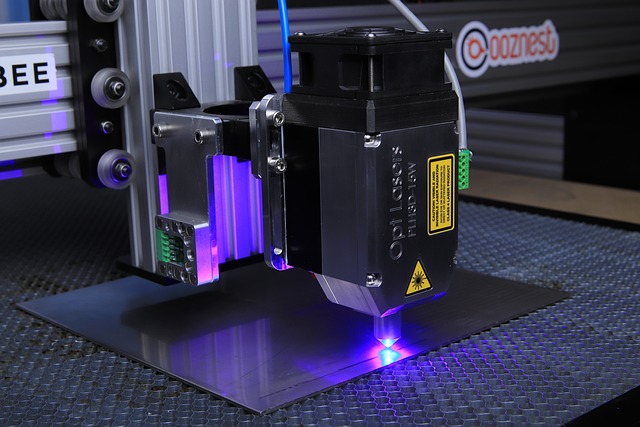

I believe that using a laser machine for metal in arts and crafts projects is a game-changer. Not only does it provide precision and accuracy, but it also opens up a world of possibilities for creativity. With a laser machine, you can easily cut, engrave, and etch metal with incredible detail. The best part is that it saves time and effort compared to traditional methods, allowing you to focus on your art rather than tedious tasks. Join us in exploring the endless benefits of using a laser machine for metal!

Creative Projects You Can Make with a Laser Machine

Creative Projects You Can Make with a Laser Machine: If you’re looking to take your crafting to the next level, a laser machine is a must-have tool. From intricate wood carvings to personalized gifts, the possibilities are endless. With a laser machine, you can create unique home decor, custom jewelry, personalized stationery, and so much more. Let your imagination run wild and see what amazing things you can make with this versatile tool!

Jan 8, 2023 … Carbide 3D Community Site … I might be more advantage to upgrade to a larger machine and add a laser or simply buy a dedicated laser machine.

Add Laser to Nomad for etching/engraving ONLY metal – Carbide …

Sep 28, 2023 … THanks for taking a look at this post. I'm interested in cutting small simple shapes from aluminum thin sheet metal. I plan to cut perimeter …

Is there a hobbyist / desktop laser cutter that can cut sim parts from …

Diagram of a laser cutter Laser cutting process on a sheet of steel CAD (top) … Page 4:"High electrical/optical efficiency of up to 45%"; ^ Todd, Allen …

Jun 15, 2021 … … Laser engraving machines are inherently dangerous. The content this channel is for educational purposes only. Laser Everything LLC can not …

How to Engrave a BLACK MARK on Aluminum with a Fiber Laser …

… metal shop, and work area. … The digital fabrication center consists of a computer lab alongside a wide variety of digital tools including CNC machines, laser …

As an Amazon Services LLC Associates Program participant, we earn advertising fees by linking to Amazon, at no extra cost to you.

What safety precautions should be taken when using a laser machine for metal?

Always wear appropriate protective gear, such as safety goggles and gloves, when operating a laser machine for metal. Ensure the work area is well-ventilated to prevent the buildup of fumes and particles. Keep a safe distance from the laser beam and never look directly at it to avoid eye damage.Regularly inspect and maintain the machine to prevent malfunctions and accidents. Finally, train yourself and others on proper machine operation and emergency procedures.

Can laser machines be used on different types of metals?

Yes, laser machines can be used on various types of metals. Whether it’s aluminum, stainless steel, copper, or brass, laser technology is versatile and efficient in cutting and engraving different metals with precision. The key lies in adjusting the laser settings based on the specific metal’s composition and thickness. With the right parameters, laser machines can deliver high-quality results on a wide range of metals, making them a valuable tool for metal artistry and craftsmanship.

How do laser machines compare to traditional metal cutting tools?

Laser machines offer precision and speed that traditional metal cutting tools simply cannot match. The technology allows for intricate designs and accurate cuts without the mess and limitations of traditional methods. While traditional tools may have their place in certain applications, laser machines are the future of metal cutting due to their efficiency and versatility.

When it comes to metal cutting with laser machines, precision and accuracy are paramount. Ensuring your cuts are precise can elevate your arts and crafts projects to a professional level.

Increased efficiency and productivity in metal crafting can revolutionize your artistic projects, allowing for faster creation and smoother workflows.

Being able to create intricate designs and patterns adds a unique flair to your artistic projects. It allows for endless creativity and personalization, making each piece truly one-of-a-kind.