As an Amazon Services LLC Associates Program participant, we earn advertising fees by linking to Amazon, at no extra cost to you.

Choosing the Right Plasma Laser Cutting Machine

Selecting the proper plasma laser cutting machine is crucial for any artistic endeavor. Consider the thickness and type of material you’ll primarily work with, as this impacts the machine’s power requirements. I highly recommend looking for machines with adjustable settings for precision cutting. Size matters, too; ensure your workspace can accommodate the machine’s footprint. Lastly, don’t overlook customer support and warranty options. A reliable manufacturer can make a huge difference during installation and maintenance.

Popular brands and models to consider

Here are some standout brands and models that I personally recommend for your arts and crafts projects.

- Crayola: Their products, from markers to colored pencils, are reliable and vibrant. I always trust Crayola for quality coloring supplies.

- Faber-Castell: Known for their exceptional colored pencils and watercolors, Faber-Castell is a favorite among serious artists and hobbyists alike.

- Cricut: The Cricut machine is a game-changer for DIY enthusiasts, enabling intricate cuts and designs on various materials.

- Knit Picks: They offer a fantastic selection of yarn that caters to knitters of every level. My go-to for affordable, high-quality yarn.

- Blick Art Materials: A trusted source for art supplies, Blick offers a wide range of paints, canvases, and tools that keep my creativity flowing.

Creative Applications of Plasma Laser Cutting

Plasma laser cutting opens up a world of creative possibilities. I’ve seen artists transform sheets of metal into intricate wall art or stunning sculptures that draw the eye immediately. The precision and versatility of plasma cutting allow for the creation of detailed patterns that would be difficult to achieve with traditional methods. From personalized designs to functional art pieces, the applications are endless. I’ve crafted custom jewelry and home décor items, utilizing the ability to cut complex shapes with ease. This technique not only enhances the aesthetics of a project but also brings a modern twist to age-old craft practices.

Where to buy, register systems, training and customer service for Hypertherm products including industrial waterjet, laser, and plasma cutting systems, …

Sep 16, 2023 … Infinity Name Sign for Plasma, Laser, Vinyl and Other Cutters in Adobe Illustrator. The Webb Ranch · 13:31 · Design A She Shed Sign For Cricut …

Messer Cutting Systems offers all the cutting solutions you need. Learn about our plasma cutting systems and more!

Messer Cutting Systems: Plasma Cutting Systems – Cutting Solutions

TOPLOONG CNC PLASMA LASER CUTTING MACHINE. @toploongcnc. 1.74K subscribers•870 … USER SITE 4 SET MACHINE #plasma #cnc #machine #welding #automatic …

These CNC plasma cutting machines were, however, generally limited to cutting … This allows near-laser precision on plasma cut edges. Several …

Top projects you can create with a plasma laser cutter

Here are some exciting projects that can truly showcase the capabilities of a plasma laser cutter.

- Custom Metal Signage: I love creating personalized signs for businesses or home decor. A plasma laser cutter can precisely cut through metal sheets, allowing for intricate designs and lettering that can elevate any space.

- Artistic Sculptures: This tool opens a world of possibilities for creating stunning 3D sculptures. I enjoy turning flat metal pieces into abstract art or recognizable shapes, offering depth and character to any setting.

- Intricate Jewelry: The precision of a plasma cutter allows for the design of unique metal jewelry pieces. I often experiment with cutting patterns that make earrings and pendants that are both trendy and distinct.

- Functional Home Decor: I like making items like candle holders or wall art with functional designs. A plasma cutter can create pieces that are not only beautiful but also practical for everyday use.

- Custom Furniture Accents: Placing a personal touch on furniture can transform an ordinary piece. Using a plasma laser cutter, I’ve designed legs or decorative panels that enhance the overall aesthetic of tables and cabinets.

- Unique Gifts: Customized gifts are always fun to give. I find that utilizing a plasma cutter to engrave or cut personalized items for friends and family results in special, memorable presents.

Key features of plasma laser cutters

Plasma laser cutters are game-changers in various creative applications, offering precision and versatility.

- Exceptional Precision: I can achieve intricate designs with an accuracy that’s hard to find elsewhere.

- Speed: The cutting process is impressively rapid, allowing for quicker project completion without sacrificing detail.

- Versatility with Materials: I can cut through a range of materials including metal, wood, and even plastics, expanding my creative options.

- Low Heat Affected Zone: The heat impact on the surrounding material is minimal, reducing warping and maintaining the integrity of my projects.

- User-Friendly Control: Modern plasma cutters feature intuitive controls, making it easier for anyone to operate effectively.

- Cost-Effectiveness: While the initial investment might be significant, the efficiency and durability lead to long-term savings.

Essential tools and materials for plasma laser cutting

This section explores the critical tools and materials necessary for effective plasma laser cutting.

- Plasma Cutter: The device that ionizes gas to create plasma, capable of cutting through metals with precision. Investing in a high-quality plasma cutter is non-negotiable if you want clean cuts.

- Protective Gear: Don’t skimp on safety. A solid welding helmet, gloves, and flame-resistant clothing are essential for protecting yourself from sparks and UV exposure.

- Air Compressor: Plasma cutting requires a dedicated air source. A reliable air compressor is crucial for providing the necessary airflow that enhances cutting performance.

- Cutting Table: A sturdy cutting table or workstation keeps your material secure and organized. This isn’t just about convenience; it profoundly affects accuracy.

- Material Selection: Knowing which metals work best with your plasma cutter, such as stainless steel, aluminum, and mild steel, can greatly influence the outcome of your projects.

- Consumables: Invest in quality electrodes and nozzles for your plasma cutter. These components wear out over time, so having spares is vital to maintain performance.

- Ventilation System: Plasma cutting generates smoke and fumes. A good ventilation system not only improves air quality but is necessary for maintaining a safe working environment.

Maintenance Tips for Your Plasma Laser Cutter

Regularly clean the cutting bed and surrounding areas to prevent debris buildup. Check and replace consumables like nozzles and electrodes as needed; they directly affect cut quality. Calibrate your cutter often to ensure precision and accuracy. Keep an eye on air pressure; maintaining the correct level prevents excess wear on components. Lubricate moving parts periodically to reduce friction. It’s crucial to inspect power sources and connections for any signs of wear, ensuring safe operation. Always consult the manufacturer’s guidelines for specific maintenance routines.

Advantages of Plasma Laser Cutting for Arts and Crafts

Plasma laser cutting revolutionizes the way we create art. It allows for precise cuts on a variety of materials, giving us the freedom to explore intricate designs with ease. Unlike traditional methods, it minimizes material waste and produces clean edges, which means less finishing work afterward. This technology also opens up new avenues for creativity, enabling unique shapes and patterns that would be challenging to achieve otherwise. The speed of plasma laser cutting accelerates our projects, making it possible to tackle both small crafts and larger installations without compromising quality.

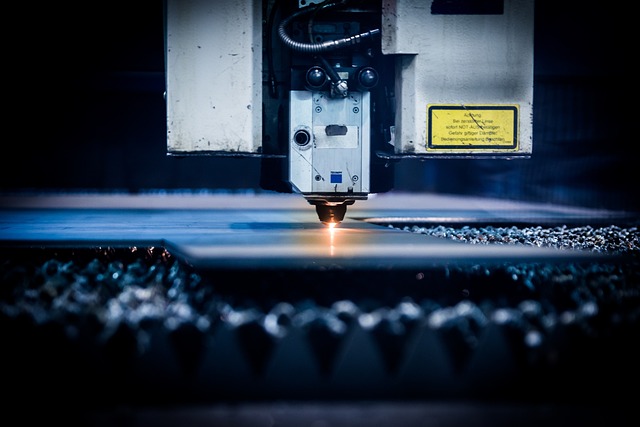

Understanding Plasma Laser Cutting Technology

Plasma laser cutting is a fusion of both laser precision and plasma energy. I firmly believe it offers unparalleled capabilities for intricate designs in arts and crafts. The technology utilizes high-velocity plasma arcs, which vaporize material with remarkable speed and accuracy. What sets plasma cutting apart is its ability to cut through a variety of materials, including metals, plastics, and even wood. This versatility opens a world of possibilities for creative projects. Additionally, I appreciate how plasma cutting minimizes waste, making it eco-friendly—a must for any conscientious artist!

As an Amazon Services LLC Associates Program participant, we earn advertising fees by linking to Amazon, at no extra cost to you.

What materials can be cut with a plasma laser cutter?

Plasma laser cutters excel at slicing through a range of metals. I frequently use them on materials like steel, aluminum, and stainless steel. They can also work effectively on copper and brass. For non-metals, you’re looking at options like acrylic and some composites, although their performance varies significantly. It’s crucial to consider material thickness; thinner materials yield cleaner cuts. Experimentation is key because not every plasma cutter will handle all materials equally well.

Is a plasma laser cutter suitable for beginners?

I believe plasma laser cutters can be quite challenging for beginners. These machines require a good understanding of mechanical setups, safety protocols, and materials handling. Although some beginner-friendly models exist, the learning curve can be steep. If you’re serious about jumping in, comprehensive training and practice are essential. Additionally, the precision and control needed can overwhelm new users. For novices, starting with simpler tools may be wiser before transitioning to plasma cutters. This way, you can build your skills and confidence gradually.

How can I create intricate designs with plasma cutting?

Designing intricate patterns with plasma cutting demands precision and planning. First, sketch the design you envision. Use vector graphic software to create clean, detailed files that a plasma cutter can interpret. Keep in mind the thickness of the material and the capabilities of your plasma cutter. Experiment with different settings to achieve desired effects. Incorporate a steady hand when guiding the torch for smooth lines. Don’t overlook test cutting on scrap material—this helps perfect your technique. Lastly, the quality of your consumables plays a significant role; using high-grade electrodes and nozzles ensures cleaner cuts.

What safety precautions should I take while using plasma cutters?

Always wear appropriate personal protective equipment (PPE), including a welding helmet with the correct shade, gloves, and fire-resistant clothing. Ensure your workspace is well-ventilated to prevent the accumulation of harmful fumes. Keep flammable materials away from your cutting area to reduce fire risks. Confirm that all electrical connections are secure to avoid shocks. Lastly, never operate plasma cutters near water or other conductive surfaces. These precautions are essential for safe operation.

Can a plasma laser cutter be used for both small and large projects?

Absolutely, a plasma laser cutter excels in versatility. I’ve used it for intricate designs as well as large-scale projects, and the results never disappoint. For small projects, it offers precision that traditional methods can’t match. On the other hand, for larger pieces, its speed and power save significant time while maintaining quality. Whatever your project scale, this tool adapts to your needs seamlessly, enhancing creativity.

A quality machine unlocks creative potential by providing precision and efficiency. I’ve experienced firsthand how an upgraded tool enhances my work, allowing me to experiment and expand my artistic boundaries.

Plasma laser cutting transforms how we create, allowing for unparalleled precision in intricate designs. This technology unlocks endless possibilities, ensuring every detail shines.

Consistent upkeep of your crafting tools and materials ensures they remain effective and reliable. I’ve learned that regular cleaning, sharpening, or replacing components directly impacts my project’s quality and my overall enjoyment of the process.